|

|||||||||||

|

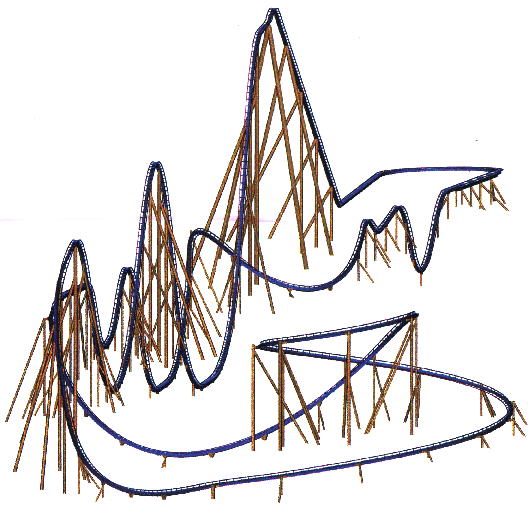

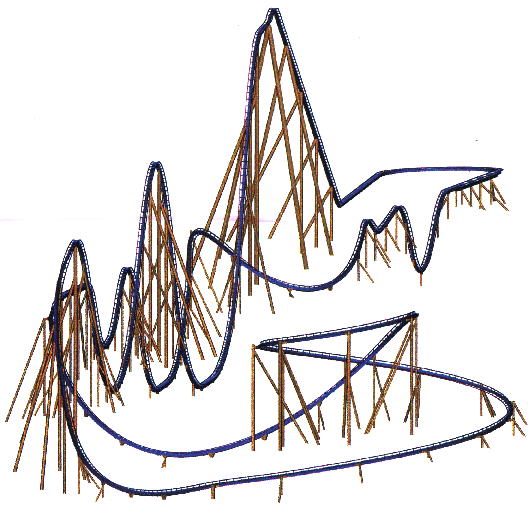

Roller coaster design has changed quite a bit since it's humble icy beginnings. Tracks can now be steel, wooden, inverted, suspended, looping, and many more variations. Safety features such as pneumatic breaks and shoulder restraints have improved ride quality as well. Even the design process has changed. John Miller's rides were designed on paper, ordered from a catalog, and built from blueprints in a few weeks. (pictured below) Today rides are designed using 3-D computer models and built for the site they will stand on. It takes over two years to design and build a single coaster for one park. To the left is a computer sketch of the design of "Apollo's Chariot" at Busch Gardens Williamsburg. | ||||||||||

|

|||||||||||

| A roller coaster can cost an amusement park up to $18 million. Did I mention that they are also three times as tall and twice as fast as Miller built them in the twenties? The actual design process for roller coasters is a complicated one. A design firm like Vekoma or Bolliger and Mabillard begins with a concept. Their engineers will draw a storyboard for the ride much the same way one would for an animated movie. They build models out of balsa woods and Styrofoam. They then build a model of the ride on a 3-D CAD program. They tweak the design for maximum thrills without compromising safety and comfort. The g-forces of every turn and hill are calculated. Finally, the actual construction starts. The steel or wooden supports are shipped to the park and bolted together on site. The completed ride is then tested using 200-pound sandbags and then brave human testers. The end product is one of the most exciting machines ever created | |||||||||||

|

|

||||||||||

|

|||||||||||

|

|

|||||||||||